Discovering the Versatility of Thermoplastic Elastomers

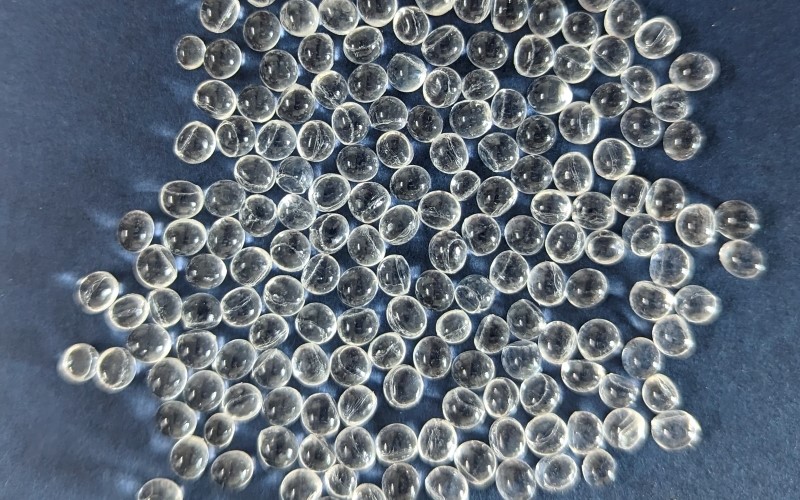

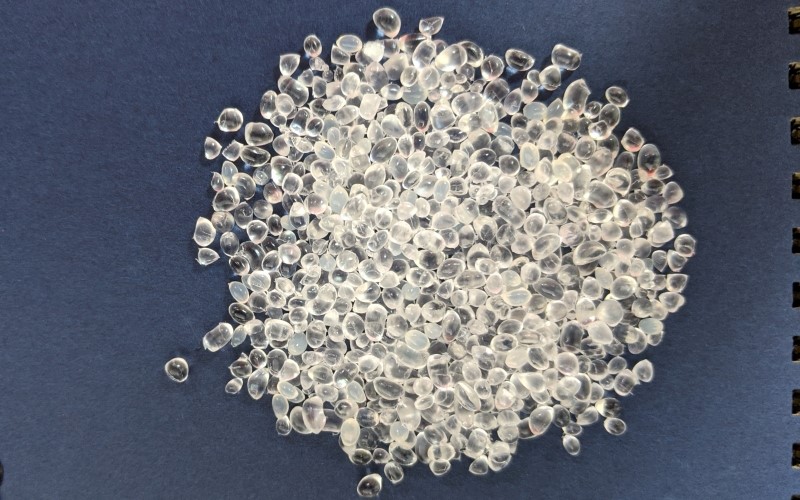

Thermoplastic Elastomer, or TPE, is a type of plastic that combines the characteristics of both thermoplastics and elastomers. This polymer has the processability and recyclability properties of thermoplastics while possessing the performance properties of elastomers, like elasticity and flexibility. TPEs can be easily melted, molded, and formed into various shapes without the need of curing or vulcanization during processing. TPE is considered one of the most versatile plastics available in the market due to their design flexibility and reduced cost. Their ability to be shaped and molded into different forms and their cost-effectiveness make them a go-to choice for many different industries and products.

Exploring the Applications of Thermoplastic Elastomers

Thermoplastic Elastomers encompass several kinds of materials, including EVA, POE, SEBS, TPEE, TPU, and more. TPE’s unique properties have gained notable popularity across different industries. It is suitable for outdoor applications due to its excellent weather resistance, chemical resistance, and durability. Additionally, its excellent durability, flexibility, and resistance to impact have made it commonly used for automotive components. With new uses continually being explored, TPEs have an increasing list of applications. Also, its versatility and recyclability make it an environmentally friendly choice in many industries.

Unparalleled Thermoplastic Elastomers Supplier

As a reliable and experienced Thermoplastic Elastomer supplier, we continue supplying premium quality TPEs and unparalleled customer service to meet the specific requirements. With years of industry experience and strict quality control, we ensure consistent performance and reliability for your applications. Trust Prochase as your Thermoplastic Elastomer supplier with our expertise. Explore the categories above for more details on TPE materials.